Green Solvent Replaces Toxic Trichloroethylene In Metal Degreasing Applications

The Problem

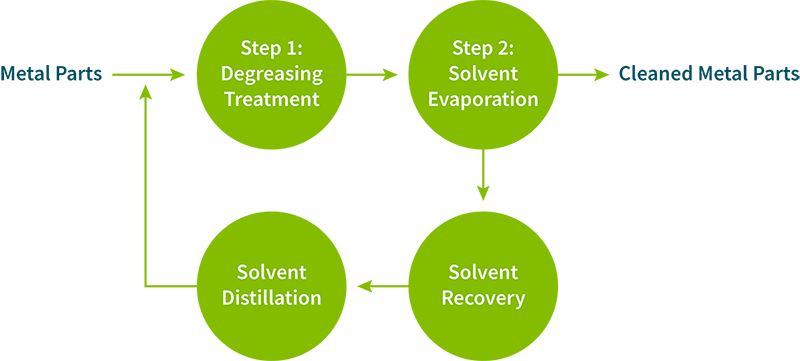

In ordinary metal processing (figure 1), metal parts are greased to avoid the corrosion process during their manufacture, storage and transport. Since the degreasing agent is incompatible with subsequent metal processing stages, a cleaning step to remove the metal protector is necessary.

Figure 1

Over the past few years, one of the major challenges in the area of metal degreasing has been the transition from fully emissive open-top systems based on the use of (eco)toxic chlorinated solvents to closed-loop metal-degreasing systems based on low VOC emission and low toxicity solvents. However, none of the proposed alternatives fully satisfy the key industrial needs of the metal finishing sector.

The Solution

A general process of ultrasound degreasing followed by solvent evaporation has been developed at InKemia laboratories. Two different representative metal parts were used to test the degreasing efficacy of a bioderived solvent. First, a steel metal part which represents a low degree of degreasing resistance. Second, we tested a sinterized steel metal part which represents the most challenging and difficult metal part because of the intrinsic porosity of the sinterized materials.

Figure 2: Environmentally derived bio based solvents have shown good performance with ultrasound degreasing systems

Ultimately the solvent showed performance and environmental benefits leading to a novel treatment preferred by manufacturers in the sector.